Automotive foam tape substrates can be divided into several types, including IXPE foam, XPE foam, high foaming PE foam, EVA foam, acrylic foam, etc. Among them, IXPE automotive foam tape is the most widely used. Using white or black foam as the substrate and red, green or blue PE release film as the release agent.

Composition of IXPE automotive foam tape:

1. Adhesive tape substrate: Using IXPE foam as the substrate, the thinnest thickness can be made to 0.1mm (even thinner than ordinary A4 paper), with common thicknesses of 1mm, 2mm, etc. The density is mainly 20 times foaming.

2. IXPE foam tape can be attached with centrifugal film, centrifugal paper, etc;

3. Adhesive tape backing: It can be single-sided or double-sided with adhesive tape. The adhesive can be divided into several types, including oil adhesive, water adhesive, hot melt adhesive, acrylic adhesive, etc.

IXPE, also known as electronic cross-linked polyethylene foam material, is characterized by a flat surface, closed cell foaming, uniform and dense pores, and stable physical properties. The specific performance is as follows:

Insulation: The IXPE automotive foam tape substrate has a closed cell structure with a fine independent bubble structure, which can prevent energy exchange caused by air convection. IXPE foam material is usually used to make insulation pipes, insulation boards, etc. Due to its anti condensation performance, it is widely used in insulation and insulation fields in humid environments such as refrigerators, air conditioners, and cold storage. It can be seen that IXPE foam is very suitable as a substrate for automotive foam tape.

Cushioning performance: IXPE foam is a semi rigid foam that does not lose its reducing performance after being subjected to strong impacts. It has good buffering performance and has been used in packaging fields such as precision instruments, semiconductors, and electronic products. As the substrate for automotive foam tape, IXPE foam can provide the tape with certain anti-collision and buffering functions.

Sound insulation: IXPE foam material has sound insulation and noise reduction functions, suitable for use as a sound insulation material in strong noise equipment such as cars, electric motors, engines, and environments.

Easy to form: IXPE has strong heat resistance, good ductility, uniform density, and can achieve deep part forming such as vacuum forming and hot forming. Therefore, it can be used as a material for automotive air conditioning evaporative cabinets, automotive hot pressed ceilings, and other interior and shoe materials.

Other properties: In addition, IXPE foam material also has non-toxic, odorless, drug-resistant properties, oil resistance, acid resistance, halogen resistance, and various other chemical properties, and is very easy to process and can be cut arbitrarily; IXPE is compatible with various materials and is a new generation of efficient, energy-saving, and environmentally friendly materials. It is precisely because of the above characteristics that IXPE becomes the best choice for automotive foam tape substrate.

Using extremely thin special foam as the substrate, the thinnest layer can reach 0 1MM, excellent waterproof performance meets international IPX7-8 standards, with ultra-high impact absorption rate, shock resistance, and sound insulation functions.

PE foam tape is made of PE foam as the base material, coated on both sides with high-performance oily acrylic adhesive, elastic foam base material, strong adhesion, good weather resistance, waterproof, solvent resistant, anti-aging, providing excellent adhesion effect on uneven surfaces.

PE foam double-sided tape refers to a double-sided tape made by applying acrylic adhesive on both sides of a PE foam substrate. The colors mainly include white, black, and gray, with commonly used thicknesses of 0.3mm, 0.5mm, 0.8mm, 1.0mm, 1.5mm, 2.0mm, and 3.0mm. The foam foaming ratio is 10 times, 15 times, 20 times, and 30 times, and the release paper (white, yellow) and release film (red, green, blue, orange) are the main release materials.

Brand: POLYSAR/OEM/ODM

Substrate: Ultra thin waterproof foam adhesiveRelease materials: printed release paper, red, transparent film, etc

Note: The above data is only a typical approximate range. The detailed parameters of each product are subject to the corresponding technical information of the product, and personalized customization services can also be provided.

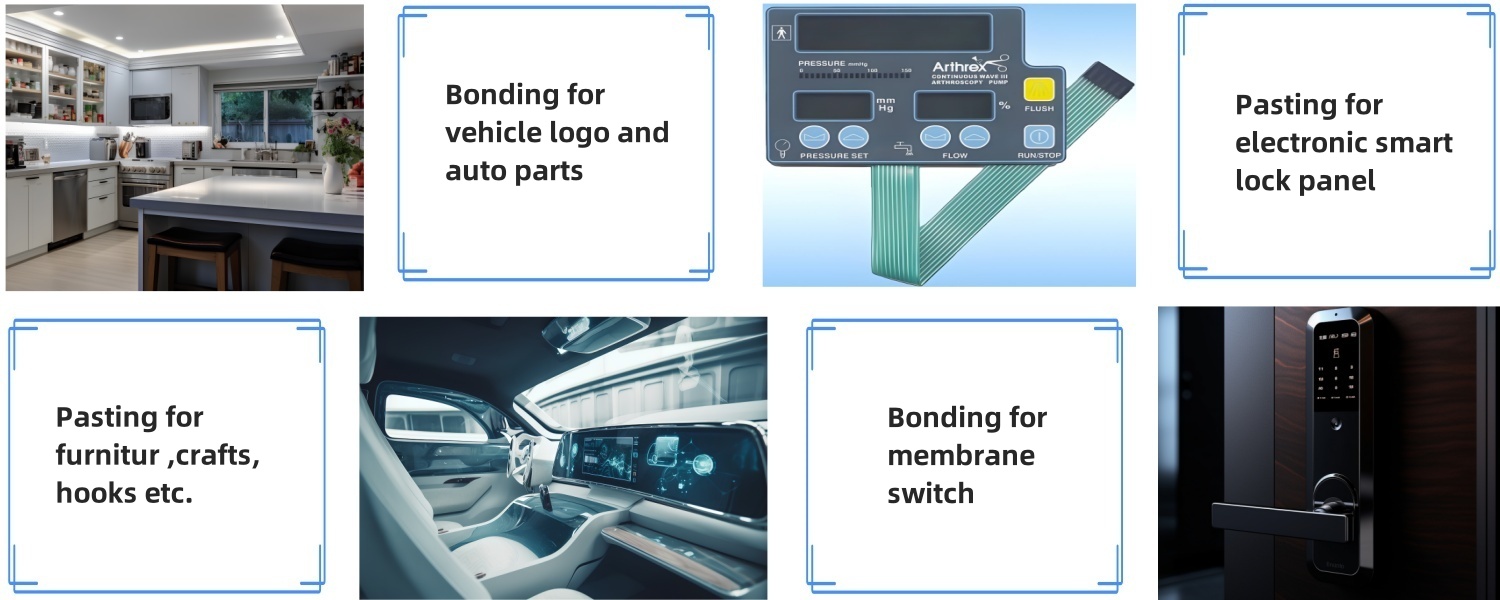

Application scenarios:

Automobile foam tape has strong adhesive force, good weather resistance, waterproof, solvent resistance, anti-aging, elastic foam base material, providing excellent adhesion to uneven surfaces.

Widely used in automotive interiors, door trims, windshields, badge pasting and fixing, etc. Strong adhesion, good shock absorption performance, and strong weather resistance. Adhesion between car and motorcycle signs, household appliances, engineering decoration, and structural bonding and fixation of curtain walls.

Adhesion and fixation of car decorative strips, car windows, car pedals, sealing strips, wave plates, wheel arches, flow blocking, brake lights, and car interior panels. PE foam tape is made of PE foam as the base material, coated on both sides with high-performance oily acrylic adhesive, elastic foam base material, strong adhesion, good weather resistance, waterproof, solvent resistant, anti-aging, providing excellent adhesion effect on uneven surfaces. Suitable for the electronics industry, furniture industry, metal, interior and exterior decoration of automobiles, logos, brands, accessories, and other aspects.